The new buzzword in coronavirus containment is “social distancing.” What is it, and what does it mean for logistics?

China has popularized application of “social distancing” in a bid to control the runaway Covid-19 coronavirus. After a slow start, China has moved aggressively in Wuhan and elsewhere. Key measures have included closing schools, quarantining entire neighborhoods, and shutting down workplaces.

Social distancing is not a new concept. As the Wall Street Journal and others have reported, experts cite this strategy as a proven approach.

“Social distancing and quarantine is an ancient practice that has been tried and tested through the ages and has survived because it works,” said Osman Dar, a global health-systems expert at Chatham House, a U.K. think tank. “In the face of an unknown virus or illness it is the most effective means of interrupting and slowing transmission.”

What does it mean for logistics?

Ever since 1980, logistics has been squeezing cost out of the global supply chain. In 1980, logistics spend represented close to 16% of GDP. Today it is closer to 9%. That savings – which is reflected in lower costs for your shirt, office chair, and coffee cup – comes from a lean, just-in-time supply chain network. The global logistics ecosystem squeezed out cost by sourcing from manufacturers in Asia, reducing the number of steps in the process, and shortening order-to-cash cycles.

But all that efficiency came at a cost. Today, we are more dependent than ever on a global network. Any supply chain is only as resilient as its weakest link. And in a world where companies may source products or rely on manufacturing in dozens of locations, we are more vulnerable than ever to supply shocks.

Coronavirus represents exactly that kind of shock to the system. It is disrupting manufacturing, distribution, and logistics, not just in China but worldwide.

As people, and companies, seek to engage in “social distancing” between one another, how will logistics adapt?

For starters, I believe companies will build up safety stock. We will shift from “just-in-time” to “just-in-case.” Companies will hold more inventory. This will cost us all more as consumers, but it will also provide more insulation.

In addition, firms are likely to shift from long-distance outsourcing to short-distance nearsourcing. Manufacturing plants for US companies are likely to relocate from China to North America. Ironically, what the Trump Administration sought to do with political tools may instead be achieved thanks to the pandemic.

Lastly, the complex web of supply chain networks may become simplified. In a world of uncertainty, companies may choose to simplify their business models, narrow their networks, and reduce their dependencies. It may be that 2020 is a “back to basics” year.

So in sum, “social distancing” may cause “supply chain narrowing.”

———-

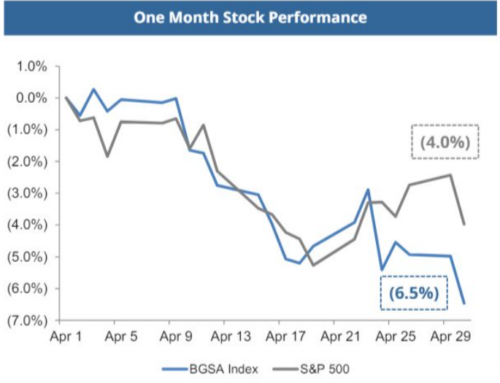

Benjamin Gordon, Cambridge Capital CEO, is an investor, advisor and board member for leading supply chain and technology companies. Visit Cambridge Capital for more. Gordon is also a frequently-quoted expert on transportation, logistics, and supply chain trends. Follow him on Twitter, LinkedIn, Medium, and his blog.