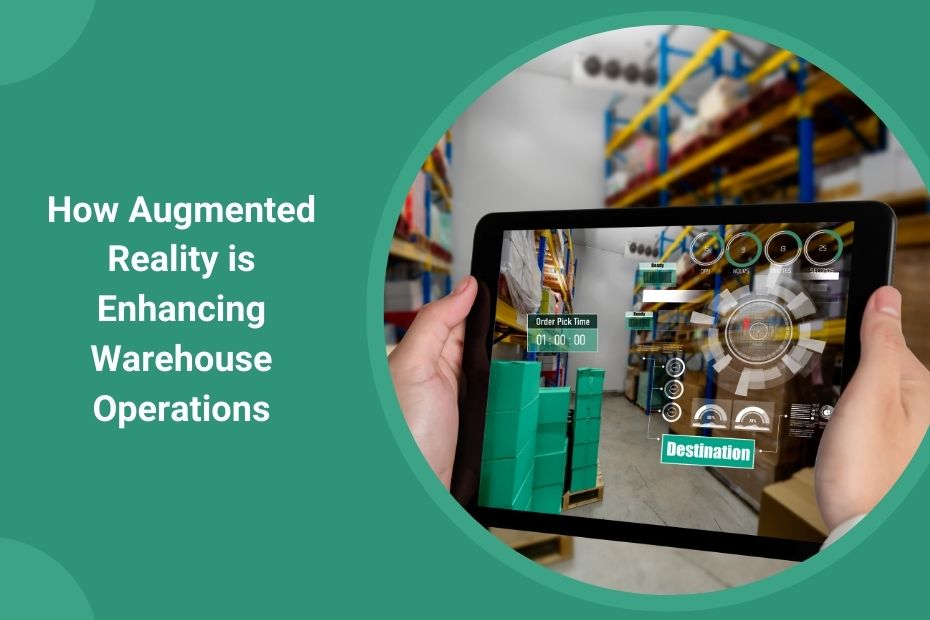

Augmented Reality (AR) is rapidly transforming warehouse operations, bringing a new level of efficiency, accuracy, and safety. By overlaying digital information onto the physical environment, AR enables workers to access critical data in real time, streamlining processes that were traditionally manual and time-intensive. Let’s explore how AR is revolutionizing warehouse operations and why it’s becoming an essential tool in modern logistics.

Streamlining Order Picking

Order picking is one of the most resource-intensive tasks in warehouse operations, often accounting for a significant portion of labor costs. AR technology is revolutionizing this process by providing workers with wearable devices, such as smart glasses, that display real-time instructions. These devices guide workers through the warehouse, highlighting item locations, optimal routes, and quantities to be picked.

For example, DHL successfully implemented an AR pilot program where workers used smart glasses to improve picking accuracy and efficiency. The results were remarkable—a 25% increase in productivity. With AR eliminating the need for printed instructions and handheld scanners, workers can focus on the task at hand, reducing errors and saving time.

Enhancing Training Programs

Training new employees in a warehouse can be time-consuming and costly. Traditional methods require hands-on practice, which not only takes up valuable resources but can also disrupt daily operations. AR offers a more effective alternative by providing immersive training experiences that simulate real-world scenarios.

With AR, new hires can interact with virtual objects and learn processes such as picking, packing, and equipment handling in a controlled environment. This approach accelerates the onboarding process and ensures employees are well-prepared before entering the warehouse floor. Additionally, AR-based training improves retention by making learning more engaging and interactive.

Improving Inventory Management

Accurate inventory management is crucial for ensuring smooth warehouse operations. AR simplifies this task by enabling workers to access real-time inventory data through wearable devices. When scanning a storage area, AR can display detailed information about stock levels, product descriptions, and expiration dates directly in the worker’s field of view.

This capability reduces the time spent searching for items and minimizes the risk of stock discrepancies. For businesses handling high volumes of inventory, AR becomes an indispensable tool for maintaining accuracy and efficiency.

Facilitating Maintenance and Repairs

Equipment downtime in a warehouse can disrupt workflows and lead to significant financial losses. AR addresses this challenge by providing maintenance teams with step-by-step repair instructions overlaid on the equipment. Instead of flipping through manuals or relying on external support, technicians can see visual guides and instructions directly on their smart glasses or tablets.

This hands-free approach speeds up repairs and ensures tasks are performed accurately, reducing downtime and improving overall equipment reliability. AR also allows for remote assistance, where experts can guide on-site technicians through complex repairs, further enhancing efficiency.

Enhancing Safety Measures

Safety is a top priority in any warehouse, and AR plays a vital role in preventing accidents and ensuring compliance with safety protocols. AR systems can alert workers to potential hazards by displaying warnings directly in their field of view. For example, if a worker approaches a restricted area or hazardous machinery, the AR device can provide a real-time alert.

In addition, AR can guide workers through safe operating procedures for handling heavy machinery or navigating busy aisles. These visual aids reduce the risk of accidents and create a safer working environment for everyone.

Optimizing Space Utilization

Efficient use of space is critical in warehouse management, especially as demand for storage capacity increases. AR helps managers optimize space by providing visualizations of storage layouts and suggesting the best configurations for organizing inventory. By analyzing real-time data, AR can identify underutilized areas and recommend adjustments to improve material flow and maximize capacity.

This capability is particularly valuable during peak seasons when warehouses need to accommodate higher inventory volumes. AR ensures that every square foot is utilized effectively, reducing costs and improving operational efficiency.

Real-World Success Stories

DHL’s AR-Powered Order Picking

DHL’s use of AR in its warehouses is a prime example of how the technology can drive efficiency. In a pilot program, workers equipped with AR smart glasses achieved a 25% increase in picking productivity. The glasses provided real-time visual instructions, guiding workers to the exact location of items and reducing the likelihood of errors.

Peter Millar’s Vision Picking

Luxury apparel retailer Peter Millar implemented AR through LogistiVIEW’s Vision Pick & Put Wall. This system provided workers with visual cues for sorting and placing items, significantly improving efficiency during peak seasons. The adoption of AR also reduced training time for new employees, enabling the company to scale operations quickly.

BMW’s Maintenance and Repairs

BMW has integrated AR into its maintenance processes, allowing technicians to view repair instructions overlaid on complex machinery. This innovation has reduced repair times and minimized equipment downtime, ensuring that production lines remain operational.

How Does AR Improve Order Picking Accuracy?

AR improves order picking accuracy by providing real-time visual instructions directly in the worker’s field of view. This eliminates reliance on printed lists or handheld devices, reducing errors and ensuring that the correct items are picked efficiently.

Key Benefits of AR in Warehousing

- Increases picking efficiency by up to 25%.

- Reduces errors in order fulfillment and inventory management.

- Accelerates training through immersive simulations.

- Decreases downtime with guided maintenance instructions.

- Enhances safety by providing real-time hazard alerts.

- Optimizes space utilization with data-driven visualizations.

In Conclusion

Augmented Reality is no longer a futuristic concept—it’s a practical solution that’s enhancing warehouse operations across the globe. By streamlining processes like order picking, inventory management, and equipment maintenance, AR is driving efficiency and accuracy while reducing costs. As technology continues to evolve, the applications of AR in warehousing will only expand, making it an indispensable tool for businesses aiming to stay competitive in the fast-paced logistics industry. Adopting AR today is not just about keeping up with trends; it’s about setting the foundation for a smarter, more efficient future.