In the competitive and rapidly evolving world of business, supply chain collaboration has emerged as a key strategy for enhancing efficiency, reducing costs, and improving customer satisfaction. Effective collaboration between supply chain partners can lead to significant improvements in overall performance, resilience, and innovation. This article explores five essential strategies for enhancing supply chain collaboration, offering practical insights into how businesses can build stronger partnerships and achieve mutual benefits. By implementing these strategies, companies can create more robust and agile supply chains capable of responding to market demands and disruptions effectively.

1. Establish Clear Communication Channels

Clear and consistent communication is the foundation of successful supply chain collaboration. Effective communication ensures that all parties are aligned on goals, expectations, and processes, which is crucial for minimizing misunderstandings and fostering a cooperative environment. Businesses should establish robust communication channels that allow for real-time data sharing and regular updates. Digital platforms and collaboration tools, such as supply chain management software and cloud-based communication systems, facilitate seamless communication between partners. Regular meetings, both virtual and in-person, help maintain transparency and address any issues promptly. Moreover, fostering a culture of open communication encourages partners to share valuable insights and feedback, leading to continuous improvement and innovation within the supply chain. By leveraging technology to enhance communication, businesses can ensure that all stakeholders are informed and engaged, leading to more effective collaboration.

2. Align Goals and Objectives

For supply chain collaboration to be effective, all parties involved must have aligned goals and objectives. This alignment ensures that every participant is working towards the same outcomes, reducing conflicts and enhancing cooperation. Businesses should engage in joint planning sessions where they can discuss their long-term and short-term goals, identify mutual benefits, and develop a shared vision. This process helps in setting clear performance metrics and milestones that are agreed upon by all partners. Aligning goals also involves understanding each partner’s strengths and weaknesses, which can be leveraged to create a more efficient and productive supply chain. For instance, if one partner excels in logistics while another has superior manufacturing capabilities, combining these strengths can lead to better overall performance. Regularly revisiting and adjusting these goals as needed ensures that the collaboration remains relevant and effective in achieving desired outcomes.

3. Invest in Technology and Infrastructure

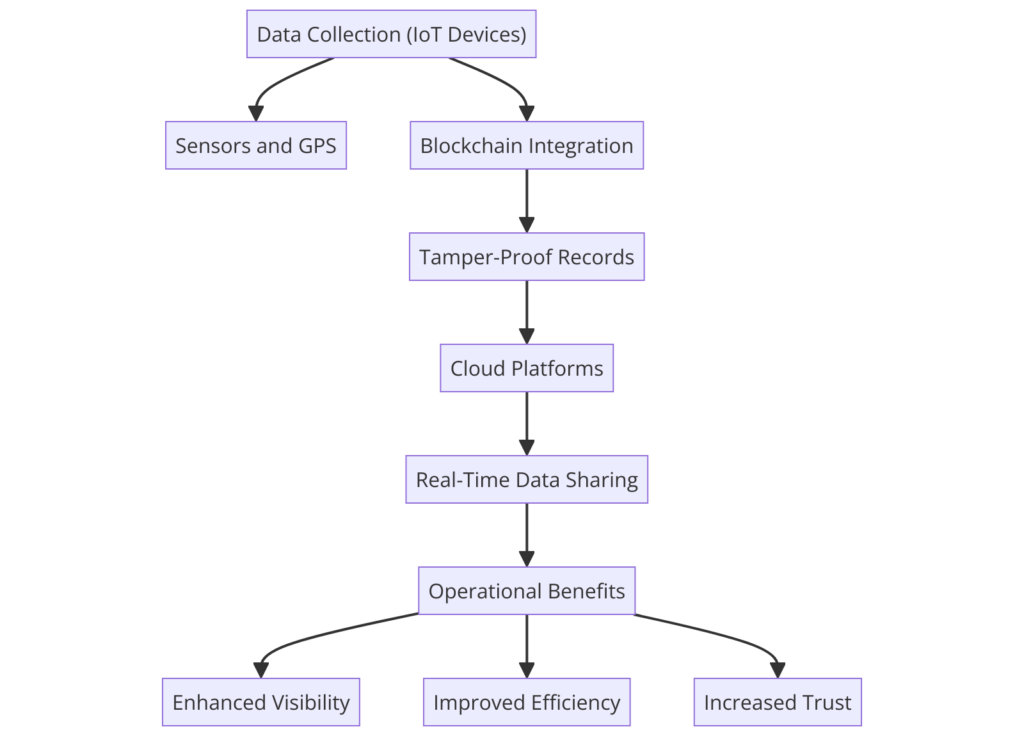

“Investing in IoT, blockchain, and cloud platforms enhances real-time data sharing, visibility, and operational efficiency in supply chains.”

Investing in the right technology and infrastructure is crucial for enabling effective supply chain collaboration. Advanced technologies such as cloud-based platforms, Internet of Things (IoT), and blockchain can facilitate real-time data sharing and enhance visibility across the supply chain. These technologies enable partners to monitor and manage the flow of goods, track shipments, and optimize inventory levels efficiently. Additionally, integrating supply chain management software can streamline processes and improve coordination between partners. For example, IoT sensors can provide real-time updates on the condition and location of goods, while blockchain can ensure the integrity and transparency of transactions. Investing in technology not only enhances operational efficiency but also provides the analytical tools needed to make informed decisions and respond quickly to disruptions. By adopting these technologies, businesses can create a more connected and responsive supply chain, capable of meeting the demands of a dynamic market.

4. Foster Trust and Transparency

Trust and transparency are critical components of successful supply chain collaboration. Building trust takes time and requires consistent effort from all parties. Businesses should start with small, manageable projects that deliver quick wins and build momentum. Transparent practices, such as sharing accurate and timely information about inventory levels, forecasts, and order statuses, help in establishing trust. Moreover, adopting clear and fair policies regarding profit-sharing, risk management, and conflict resolution can further strengthen the partnership. When partners trust each other, they are more likely to engage in open communication and collaborate effectively, leading to better outcomes for the entire supply chain. Trust also facilitates more flexible and adaptive partnerships, allowing companies to respond more effectively to changes and challenges in the market. Establishing governance structures that support transparency and accountability is essential for maintaining trust over the long term.

5. Develop Joint Risk Management Strategies

Collaborative risk management is essential for mitigating the impact of supply chain disruptions. Partners should work together to identify potential risks, assess their impact, and develop strategies to manage them. This can include creating joint contingency plans, diversifying suppliers, and investing in risk mitigation technologies. Regular risk assessment exercises and scenario planning can help partners stay prepared for unforeseen events. By sharing resources and knowledge, partners can enhance their ability to respond to disruptions and maintain supply chain continuity. For example, joint investments in technology such as predictive analytics can help partners anticipate and manage risks more effectively. Additionally, collaborative risk management fosters a sense of shared responsibility and commitment to maintaining a resilient supply chain. Establishing clear roles and responsibilities for risk management ensures that all partners are actively involved and prepared to address potential challenges.

In Conclusion

Effective supply chain collaboration requires clear communication, aligned goals, investment in technology, trust, transparency, and joint risk management. By implementing these strategies, businesses can enhance their supply chain performance, reduce costs, and improve customer satisfaction. Collaboration enables companies to leverage each other’s strengths, share resources, and create more agile and resilient supply chains. As the business environment continues to evolve, staying ahead of the competition will depend on the ability to collaborate effectively and respond to market demands swiftly. Embracing these collaborative strategies will pave the way for sustained growth and success in the dynamic world of supply chain management. By fostering strong partnerships and continuously improving collaborative practices, businesses can build supply chains that are not only efficient but also capable of withstanding the challenges of a rapidly changing global market.